Core solution

Crops for Processing

Crops for Processing (CfP) is a global standard that aims to support the safe and responsible production of plants destined for further processing. Designed as a holistic standard, it eliminates the duplication of steps usually conducted by both the producer and the processor.

Meet demand for responsibly sourced raw materials

What is Crops for Processing?

Crops for Processing (CfP) is a farm-level, nonaccredited standard for producers of fruit and vegetables, combinable crops, and green coffee. It is designed for producers who supply produce exclusively for further processing in the supply chain – from freezing, juicing, roasting, milling, precooking, and more to ingredients for animal feed. The standard considers the unique farm-level risks of producing crops for processing and integrates action taken by processors at agreed control points, reducing the duplication of production steps. CfP is tried, tested, and trusted around the world, with CfP-certified production processes covering more than 21,000 hectares annually.

CfP at a glance (as of 31/12/2022)

Offers certification

targeted at crops destined for canning, freezing, juicing, fermenting, roasting, milling, precooking, animal feed, and more

Adopts a holistic approach

that aims to address food safety, environment, traceability, and workers’ health, safety, and welfare

Provides certification options

for a variety of farm sizes and types, including smallholders and producer groups

Reduces duplication

of production steps that may be conducted by both the producer and the processor

Addresses market demand

from brands and retailers for processed products whose raw materials originate from certified production processes

Implemented worldwide

with a global network of approved CBs and Registered Trainers

Offers certification

targeted at crops destined for canning, freezing, juicing, fermenting, roasting, milling, precooking, animal feed, and more

Reduces duplication

of production steps that may be conducted by both the producer and the processor

Adopts a holistic approach

that aims to address food safety, environment, traceability, and workers’ health, safety, and welfare

Addresses market demand

from brands and retailers for processed products whose raw materials originate from certified production processes

Provides certification options

for a variety of farm sizes and types, including smallholders and producer groups

Implemented worldwide

with a global network of approved CBs and Registered Trainers

Which topics does CfP address?

CfP has been developed together with sector experts and underwent extensive public consultation as part of our process for standard setting. This ensures that CfP remains robust, realistic, and cost-efficient for producers while meeting the evolving demands of buyers. Core topics in CfP v1.1 include:

Site history and management

Recordkeeping and internal self-assessment

Workers’ health, safety, and welfare

Waste and pollution management, recycling and reuse

Soil management and conservation

Food defense and food fraud mitigation

Traceability, segregation, and mass balance

Plant propagation material

Fertilizer and plant protection product application

Water management

Discover more about how CfP helps you address challenges in the agricultural sector.

Who should use CfP?

CfP is suitable for any producers – or processors cultivating their own crops – who grow produce solely for processing (i.e., no produce destined for fresh consumption). For producers who supply fresh produce, we recommend the Integrated Farm Assurance (IFA) standard. Supply chain processing can include a wide range of final products such as:

Canned/Dehydrated/Fermented/Frozen fruit and vegetables

Fruit and vegetable juices

Flours

Cooking oils

Sauces

Wines

CfP requires the processor to take over the necessary “kill steps” that mitigate food safety risks, and all processors must have certification recognized by the Global Food Safety Initiative (GFSI). These include BRCGS, International Featured Standards (IFS), and Food Safety System Certification (FSSC).

CfP can be applied to both covered and noncovered production and offers certification options for both individual producers (single site and multisite producers) and producer groups, including smallholders. Producers can get certification in any country where a GLOBALG.A.P. approved certification body (CB) conducts audits.

How does CfP work?

Compliance with the standard requirements is audited every three years by an accredited and independent third-party CB.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

In the intervening years, producers conduct a self-assessment/second-party internal inspection and, if they are an Option 2 producer group, a quality management system (QMS) audit.

Both self-assessments/second-party internal inspections and third-party CB audits require the “Overview of Farming Operations” form to be completed. This is part of the CfP checklist and includes questions about the producer’s and processor’s responsibilities.

A successful CB audit results in a certificate valid for one year.

As processors and manufacturers are already held to robust standards such as BRCGS, IFS, or FSSC, certain obligations and control points, which would usually be managed at farm level, can instead be managed by the processor.

A contract between the producer and the processor establishes the rights and obligations of each party. Under this contract, the processor takes steps necessary to mitigate food safety risks. This can include aspects such as pathogen eradication (through pasteurization, roasting, or freezing, etc.), residue testing, or water analysis.

The standard is composed of control points and compliance criteria (CPCCs). CPCCs are graded in three levels: Major Must, Minor Must, and Recommendation.

Control points

Fundamentals that set the foundation of a GLOBALG.A.P. requirement

Written in question form

Compliance criteria

Methods that producers can use to demonstrate a control point to be true

Evidence required for demonstrating that the outcome is achieved

Read more about the audit process and standard requirements.

How is certification status verified?

Every producer registered in the GLOBALG.A.P. certification system is assigned a 13-digit GLOBALG.A.P. identification number (e.g., a GLOBALG.A.P. Number (GGN)). This number allows verification of certification status in the GLOBALG.A.P. IT platform, upholding our rigorous transparency requirements throughout the supply chain. GLOBALG.A.P. identification numbers for CfP can be recognized by the prefix GGN CFP – for example: GGN CFP1234567891011.

Producers can control data access and privacy rights for audit reports, and the reports are not shared publicly or with third parties. This process is handled via your chosen CB.

What is the difference between CfP and IFA?

CfP certification is very similar to IFA certification for plants, with the exception of two areas. Produce destined for processing entails different risks at farm level, and CfP therefore has a different approach to food safety risk assessment. The two standards also have different auditing rules.

It is not possible for a producer to register one crop under both standards. If part of the crop is consumed fresh, it requires IFA certification. In this case, the production processes for the whole crop must be certified to IFA, which covers more risks and is appropriate for fresh produce. A producer may, however, register one crop under IFA and a different crop under CfP.

Differences between IFA and CfP

| IFA | CfP |

|---|---|

| Covers a range of product categories under the plants and aquaculture scopes. | Only covers the product categories fruit and vegetables, combinable crops, and green coffee. |

| Crops can be for fresh consumption and are not necessarily processed after harvest. | Crops are not for fresh consumption and are always processed after harvest. |

| The IFA certificate is valid for one year, and a CB audit must be conducted annually for the producer to maintain their certification status. | The CfP certificate is valid for one year, but a CB audit is only required every third year. The producer conducts a self-assessment/second-party internal inspection in each intervening year to maintain their certification status. |

| The processor is outside of the certification scope. | A clear and defined link to the processor is required, establishing rights and obligations. |

| Producers are identified via a GGN. | Producers are identified via a GGN CFP. |

Corporate news and events have moved!

All the latest updates can now be found on the Agraya website – connecting people, ideas, and solutions across the global farming network.

Looking for technical news?

Technical news updates for core solutions can be found in our technical news libraries.

Demonstrate commitment to safer and more responsible farming

Why choose Crops for Processing?

Crops for Processing (CfP) seeks to enable producers worldwide to assess, demonstrate, and improve safe and responsible farming practices. CfP certification provides a practical and cost-efficient path for producers to implement best practices at farm level that cover the key topics of food safety, environment, workers’ health, safety, and welfare, and traceability.

Which industry challenges does CfP address?

Food safety and traceability have long been fundamental priorities for both consumers and supply chain stakeholders.

Compounded by recent changes in the legal environment for supply chains, the demand from brands and retailers for certified raw materials is increasing.

The farming industry must continuously evolve to also address the increasing interaction between the environment and agriculture, and improve farming practices in areas such as biodiversity, water management, and agricultural input use.

Responsible production is also about people, and workers’ health, safety, and welfare are in the spotlight due to social issues in new legislation in global supply chains.

The result is that buyers are seeking a growing range of assurances about, and producers are undergoing an increasing number of audits to satisfy them.

CfP offers a cost-efficient standard that reduces audit duplication and provides assurance to buyers through a holistic approach that addresses major sector demands.

Follow our five steps to certification to get started today.

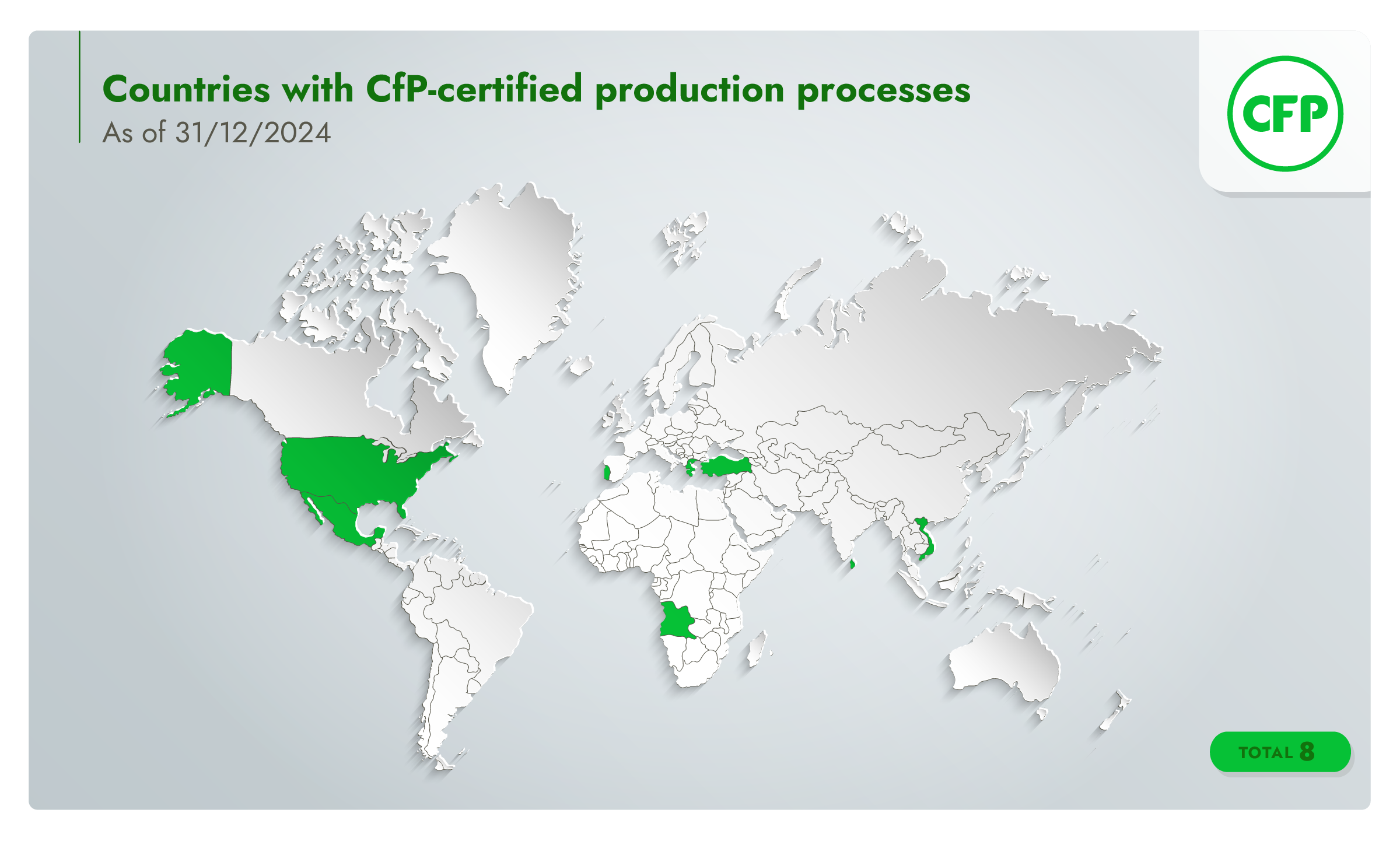

CfP in numbers (as of 31/12/2024)

1,865

producers under certification

8

countries with certified production

21,023

hectares of certified production

1,865

producers under certification

8

countries with certified production

21,023

hectares of certified production

What are the benefits for producers?

Implement a dedicated standard for the production of crops farmed exclusively for further processing.

Improve farm management and the efficiency of farm operations, with responsibility for certain control points passed down the supply chain to the processor to reduce duplication.

Get recognition for efforts to mitigate food safety risks, protect environmental resources, and monitor biodiversity on the farm.

Achieve compliance with a globally recognized standard that fulfills international supply chain requirements.

Apply our farm assurance solutions on a wide range of farm types and sizes and access certification options for both individual producers and producer groups.

Choose from an extensive worldwide network of accredited, GLOBALG.A.P. approved certification bodies (CBs).

What are the benefits for supply chain stakeholders?

Access a flexible farm assurance portfolio that provides all the coverage you need through one certification system.

Reduce audit duplication in cases where processors already fulfill standard requirements through existing certification or legal compliance.

Support industry-driven smart farm assurance solutions – developed by the sector, for the sector – that enable buyers to easily identify suppliers that fulfill their requirements.

Promote a holistic approach that features rigorous criteria on food safety, environment, workers’ health, safety, and welfare, and traceability.

Mitigate reputational risks and enable trusted supply that meets major consumer demands – from biodiversity and water management to waste and recycling.

Source from a growing pool of suppliers with certified production processes globally, with certification verification in the GLOBALG.A.P. IT platform.

Your guide to implementation

How to prepare for a Crops for Processing audit

Learn more about the key documents and fee structure of Crops for Processing (CfP). Follow our five steps to certification for an overview of the certification process, and find a GLOBALG.A.P. approved certification body (CB) in your area to get started.

Implementation and CB audit process

How does the CB audit process work?

CfP compliance is audited in the first year of certification and then every third year by accredited and independent third-party CBs.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

In the intervening years, producers conduct a self-assessment/second-party internal inspection and, if they are an Option 2 producer group, a quality management system (QMS) audit.

Both self-assessments/second-party internal inspections and third-party audits require the “Overview of Farming Operations” form to be completed. This is part of the CfP checklist and includes questions about the producer’s and processor’s responsibilities.

A successful CB audit results in a certificate valid for one year.

The CB is responsible for uploading the audit report and maintaining the accuracy of producer data in the GLOBALG.A.P. IT platform.

Which documents are required?

GLOBALG.A.P. general regulations and CfP general rules: Rules that define how the certification process works, from the scope of the standard to the audit requirements.

Checklist: The full list of control points and compliance criteria (CPCCs) as used by CB auditors, enabling producers to conduct a self-assessment.

Which versions of CfP are currently valid?

CfP is currently valid in version 1.1, published in May 2018.

The FAQ contains further information on documents, certification renewal, and more.

What are the CfP standard requirements?

CPCCs are graded in three levels: Major Must, Minor Must, and Recommendation.

To achieve certification, producers must comply with 100% of the Major Musts and at least 95% of the Minor Musts.

Corrective actions must be proposed for all non-compliances and submitted to the CB within the specified period.

Non-compliances must then be verified as corrected and compliant by the CB before a certificate can be issued.

How much does CfP certification cost?

Each farm is unique, and the total costs of certification depend on a combination of factors such as farm size, number of sites, location, necessary preparation measures (such as establishing new procedures), and more. CfP contains three cost elements:

Implementation costs: Incurred by the producer to prepare for the CB audit

CB service fees: Determined and invoiced by the CB to cover audit time and travel costs

GLOBALG.A.P. registration and certificate license fee: Calculated based on farm size and invoiced by the CB

The GLOBALG.A.P. fee table contains full information on the fee structure for each standard and add-on.

Five steps to certification

You will need the GLOBALG.A.P. general regulations, the CfP general rules, and the CfP checklist. All of the required documents are available online, for free, and in multiple languages. They are linked below and can also be found in the GLOBALG.A.P. document center.

Verify that CfP is applicable to the intended product and use the documents to guide the implementation of the standard requirements. Conduct a self-assessment using the checklist, remembering to complete the “Overview of Farming Operations” section. Our worldwide network of Registered Trainers can also provide assistance during audit preparations.

Search the list of GLOBALG.A.P. approved CBs by region, country, scope, and status. Contact the CB of your choice and request an audit. Note that the GLOBALG.A.P. fee table does not cover CB service fees such as audit time or travel costs to your site.

The CB will perform the on-site audit and upload the results to the GLOBALG.A.P. IT platform. Any non-compliances which are detected during the audit must be corrected within the specified period and verified by the CB before a letter of conformance can be issued.

Once all requirements are met and verified by the CB, they will issue your CfP certificate. Your certification status is then publicly visible in the GLOBALG.A.P. IT platform for transparency in the market.

Key documents

The three most relevant documents are linked below. Click ‘view more’ to see further related documents. Remember to always check with your CB that you have all necessary documents prior to audit.

Inspection of CfP with GRASP

Guidelines and supporting documents

V1

English | Last updated: 29/11/2024

Guidelines and supporting documents

V1

English | Last updated: 29/11/2024

Guidelines and supporting documents are developed by the GLOBALG.A.P. Secretariat to help producers understand the terminology, legal requirements, and farm-level implementation of GLOBALG.A.P. standards and add-ons.

CfP

Checklists

V1.1

English | Last updated: 29/11/2024

xlsx

Checklists

V1.1

English | Last updated: 29/11/2024

xlsx

Checklists are documents containing standard/add-on principles and criteria which are used during the audit/assessment to check whether compliance is achieved. They may also be used to conduct self-assessments.

CfP General Rules

Rules and regulations

V1

English | Last updated: 29/11/2024

Rules and regulations

V1

English | Last updated: 29/11/2024

Rules and regulations define how a specific standard must be implemented – from the certification scope to the audit requirements for certification bodies.

GLOBALG.A.P. approved CBs

The list of GLOBALG.A.P. approved CBs can be filtered by region, country, scope, and status. Click a CB to find more information and contact details.

If you do not filter your search, or filter only according to region and/or country, your search results will also show CBs that offer certification against benchmarked schemes, but which may not have approval for any GLOBALG.A.P. standards and add-ons.

Capacity building

Need assistance with the certification process? Our capacity-building program offers a range of options for training, consultation, and more!

A brief history of CfP

CfP, the first GLOBALG.A.P. standard that enables processors of juices, preserves, and other processed foods to source from uniformly monitored and responsibly farmed raw materials, is launched in 2015. The farm-level standard is largely aligned with Integrated Farm Assurance (IFA), with the exception of the auditing rules and risk-based approach to food safety. By the end of 2017, there are 67 producers under CfP certification in three countries.

The updated CfP v1.1 is launched in May 2018.

By the end of 2019, there are 348 producers under CfP certification in five countries, an increase of almost 420% on the previous year.

Adoption of the standard continues to grow in 2020, with 744 producers under certification.

By the end of 2021, there are 834 producers under certification.

There are over 20,000 hectares of production certified to CfP by the end of 2022.

The number of producers under CfP certification rises to over 1,860 at the end of 2024.

FAQ

No, processing is excluded from CfP. However, the link from the producer to the processor must always be clear, for example via a contract that specifies which party is responsible for which aspect of production/processing.

Information regarding the processor must be included in the “Overview of Farming Operations” section of the CfP checklist. Any evidence of the processor’s certification must also be made available.

The term “kill steps” refers to the part of food processing which removes bacteria from a product. This may include residue testing, water analysis, heating/cooking, freezing, roasting, pasteurization, etc. If no specific kill steps are implemented by the processor, CfP cannot be implemented at farm level.

However, there may be exceptions. In some cases, it is important to evaluate the specific crop, the process, and the history and vulnerability of the crop to food safety outbreaks. An example might be cold-press production of olive oil. If you are unsure about the applicability of the standard, please speak to your CB.

No, producers cannot register one crop (e.g., peas) under both CfP and IFA. If a part of the crop is consumed fresh, the crop production processes require IFA certification. In this case, the production processes for the entire pea crop must be certified to IFA, which covers more risks and is appropriate for fresh produce.

However, a producer may register one crop (e.g., peas) under IFA and another crop (e.g., tomatoes) under CfP, if the second crop is produced exclusively for processing.

No, CoC is not applicable for CfP. It only applies to those products originating from production processes certified to Integrated Farm Assurance (IFA) (or an equivalent benchmarked scheme/checklist).

CfP is currently valid in version 1.1.

Each farm is unique, and the total cost of certification depends on a combination of factors such as size, location, existing policies and processes, etc. The invoice from your certification body (CB) will include CB service fees to cover expenditures (determined by the CB) and the GLOBALG.A.P. registration and certificate license fee (size based, determined based on hectares of annual production).

Download the GLOBALG.A.P. fee table to learn more.

CfP documents are currently available in:

English

Spanish

All documents are located in the GLOBALG.A.P. document center. More languages are added based on demand – please contact us with requests.

CfP compliance is audited in the first year of certification and then every third year. Producers must conduct a self-assessment/second-party internal inspection in each intervening year to maintain their certification status. Contact your certification body (CB) for more information.

When developing our standards and add-ons, we aim to receive as much input and feedback as possible. With producers based in more than 135 countries around the world and stakeholders covering every part of the value chain, our standard-setting process ensures that our solutions are both fit for purpose now and built with the future in mind.

We offer public consultation periods for draft standard documents that are created by our technical experts. This helps to uphold transparency in the development, revision, and decision-making processes. The web page on standard setting outlines the development process.

Technical questions can be addressed to standard_support@agraya.com. Your query will be forwarded to the relevant technical expert.

The GLOBALG.A.P. Academy offers public trainings on our portfolio of smart farm assurance solutions, while our worldwide network of Registered Trainers offers authorized trainings and other services. See the GLOBALG.A.P. Academy course catalog or find a Registered Trainer for more information.

The CB auditor requirements for CfP are detailed in “Crops for Processing general rules: Part I – General requirements”.

Learn more about how to become a GLOBALG.A.P. approved CB or extend your auditing scope.

Industry harmonization is a key pillar of our activities. For scheme or checklist owners, GLOBALG.A.P. benchmarking provides international recognition in a highly competitive market. It also creates time- and money-saving opportunities, with the entire value chain profiting from the benefits.

For more details on benchmarking requirements, see section 2 of the GLOBALG.A.P. benchmarking regulations.

Learn more about GLOBALG.A.P. benchmarking.

No, certification to a GLOBALG.A.P. standard/holding a GLOBALG.A.P. certificate is not the same as being a GLOBALG.A.P. Community Member.

GLOBALG.A.P. Community Membership is a paid partnership opportunity, offering a variety of benefits including the ability to support the development of GLOBALG.A.P. standards and add-ons, contribute to the GLOBALG.A.P. governance structure, and access discounted services.

Learn more about how to become a GLOBALG.A.P. Community Member.

GLOBALG.A.P. trademarks may be used in a strictly B2B context and must be accompanied by a GLOBALG.A.P. identification number (e.g., the producer’s GLOBALG.A.P. CfP Number (GGN CFP)) or a QR code to a producer’s certification status in the GLOBALG.A.P. IT platform. The trademarks should never appear to consumers, for example on product packaging.

The GGN CFP may only be used by the producer that holds the valid CfP certificate. Processors may not display this number on the final processed product.

Download the GLOBALG.A.P. trademarks use: policy and guidelines and GLOBALG.A.P. trademarks use: FAQ documents for comprehensive information on rules and use cases.

Contact us

For technical/interpretation questions, please contact us at standard_support@agraya.com.

For questions about the audit process or the GLOBALG.A.P. IT platform, please contact us at customer_support@globalgap.org.